Irish Blue Limestone has been used for centuries as the material of choice for the construction of prestige buildings. It can be worked to provide colours that range from deep blue black to subtle blue grey and surface textures ranging from silky smooth to positively aggressive.

In the hands of a skilled architect, designer or mason the combination of colours and textures can bring the most mundane structure to life or produce stunning variations with the interplay between light and texture.

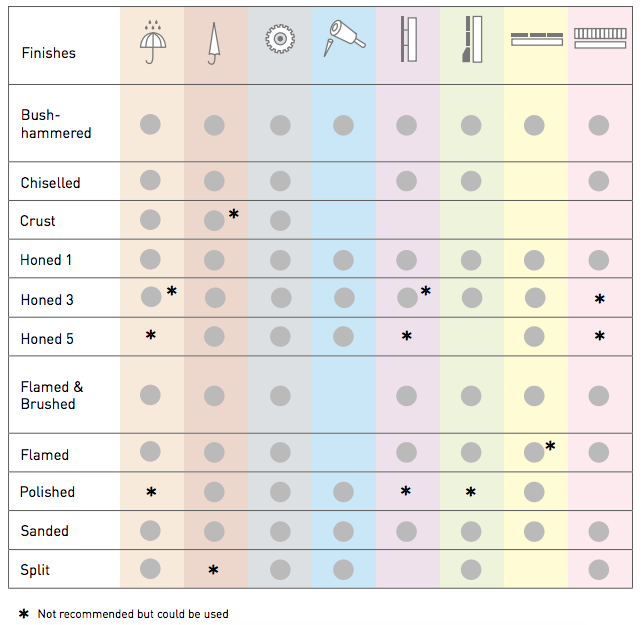

As with all materials there are some limitations on limestone thickness for the textured finishes. In a similar way some of the mechanically produced textures cannot be applied to the edges of the blocks. Polished and honed finishes generally do not perform well out of doors.

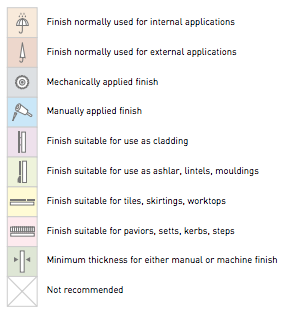

The icons associated with each finish provide a quick guide to the application and minimum thickness of the finished stone.

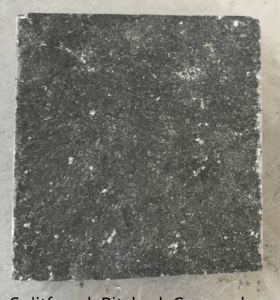

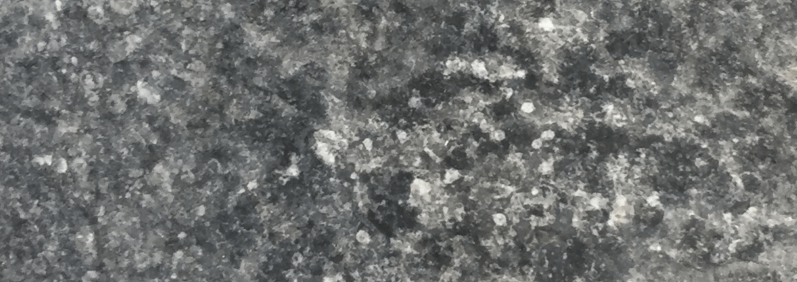

Bush Hammered Finish

Colour

Bush hammered finish has a dark blue-grey background with randomly distributed, closely spaced, contrasting paler blue-grey spots.

Finish

The surface has a smooth background with a closely spaced, randomly distributed pattern of fine dimples. Very little of the underlying limestone texture is visible but larger crinoids and white lines may show up as slightly paler areas. The appearance will vary slightly depending on the interplay of light and shadow on the surface.

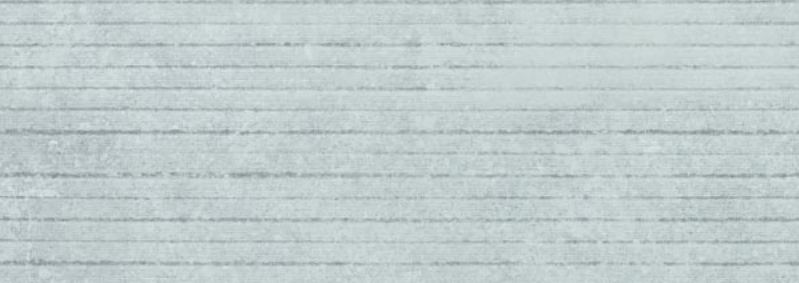

Chiselled Finish

Colour

Chiselled finishes are a pale blue-grey colour with thin sharply contrasting dark grey to black parallel lines. Crinoids will form a randomly distributed pattern of paler grey flecks.

Finish

The surface has a series of smooth parallel incised curved surfaces separated by thin lines of darker limestone. These will have minor imperfections where the calcite crystals or crinoid traces have fractured during the machining. The appearance will vary depending on the orientation of the grooves and the interplay of light and shadow on the surface.

Crust Finish

Colour

The colour can be highly variable ranging from dark blue-grey to pale brown-green depending on the beds being extracted. There can also be extensive development of white calcite.

Finish

The surface is produced by the various lithification processes during the transformation of the lime mud into the limestone and may often have slightly brown colouration due to the presence of clay minerals within the calcite. There may be considerable variations in the actual thickness of the finished material.

Flamed and Brushed Finish

Colour

Flamed faces have a translucent mottled grey colour. The tonal variations are randomly developed and very little of the underlying calcite grain structure is discernable. Crinoids will show as paler flecking.

Finish

The surface has a smooth glassy texture with an irregular overlay of minor pits and peaks.

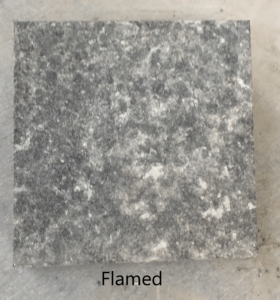

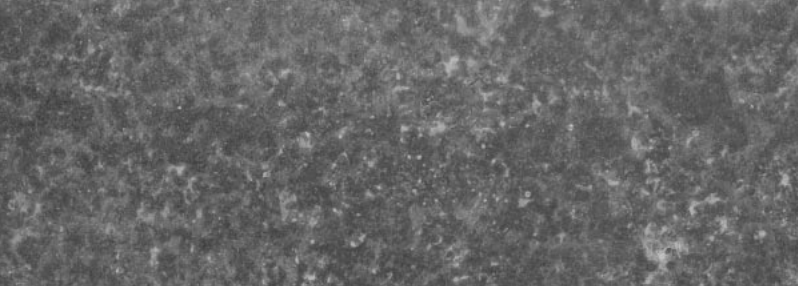

Flamed Finish

Colour

Flamed faces have a slightly translucent mottled grey colour with slightly paler areas. The tonal variations are randomly developed and very little of the underlying calcite grain structure is discernable. Crinoids will show as paler flecking.

Finish

The surface has a smooth slightly dusty appearance with an irregular overlay of minor pits, peaks and flakes.

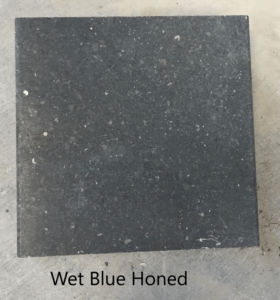

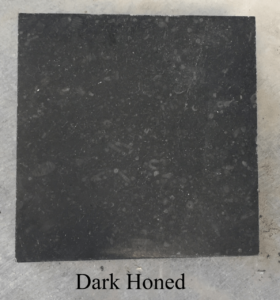

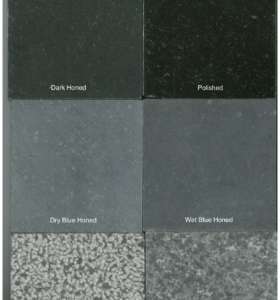

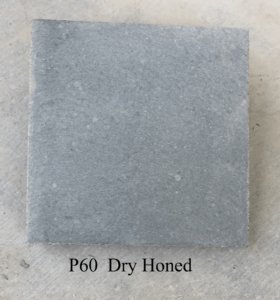

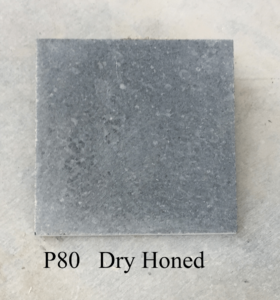

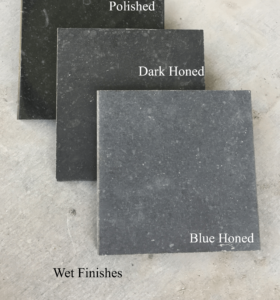

Honed Finish [1]

Colour

Honed finishes can be produced using a range of grits. The coarsest grit (1) will give a pale blue-grey colour and the finest (5) a dark blue-grey to black. There will be subtle variations between different beds in any quarry. Most quarries have a limited number of beds that yield an even colour but where crinoids are present they will show as well defined surface mottling. Shell beds honed with a fine grit are often black with a spectacular white contrast provided by the brachiopods.

Finish

The surface produced by the coarser grits (1) is smooth and matt with a faint pattern of circular scores. Finer grits (3 & 5) produce a smooth matt texture with no obvious tool marks.

Flamed Finish [3]

Honed Finish [5]

Polished Finish

Colour

Polished finishes vary from intense dark blue-grey to black but some beds may have a very slight brownish tint. The crystal structure of the calcium carbonate and the crinoids will be obvious. The white brachiopods in the shell or fossil beds will form a startling contrast to the dark even finish on these materials.

Finish

The surface has a smooth glossy texture which appears to have depth. This illusion is due to the light reflecting from the back faces of the calcium carbonate crystals forming the finished surface.

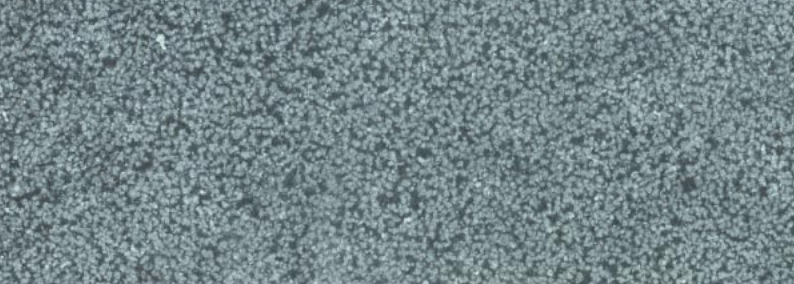

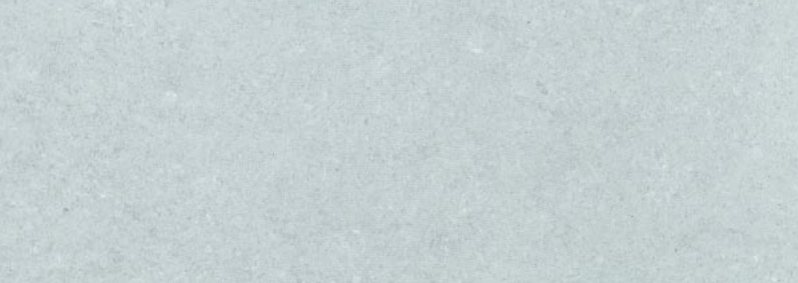

Sanded Finish

Colour

Sanded faces will normally have a pale blue-grey colour with crinoids and the calcite grain structure giving minor tonal variations.

Finish

The ground faces are flat with a faint fine pattern of scores.

Split Finish

Colour

Split face will normally have a dark blue-grey colour with random paler flecks where crinoids are present. The technique often fractures the calcium carbonate crystals giving small reflective planes that make the surface sparkle.

Finish

Splitting produces an irregular surface which may have quite high relief. Humps, hollows and pits will be randomly developed on the surface and may extend across the block edges. Ashlar traditionally had a chisel dressed edge applied to the exposed face. It will be necessary to dress areas of split stone using a point to remove the visible sawn edges.

Matrix